Injection molding is a manufacturing method usually used for fabricating objects from plastic trinkets and toys to automotive body parts, water bottles, containers, and cell phone cases. Significantly most of the plastic parts that we are using in our everyday are injected molded. It is a rapid process to make a huge amount of identical plastic products. the flexibility in shape and size attainable by the use of injection molding has constantlybroadened the borders of design in plastics and endorsedconsiderablechoices of traditional materials due to design freedom and light-weighting. Low Volume Injection Molding is a specific service that provides full protection parts that are high in quality.

How Does Injection Molding Process Work?

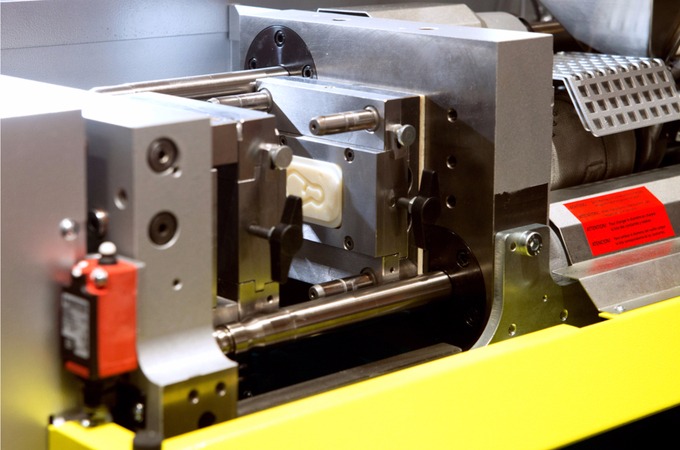

An injection machine is made up of three main components, including feed hopper, the screw, and the heated barrel. Plastic granules for the part are inserting into the heated barrel by ahopper. Plastic that is put in the hopper is normally in powder or coarse form though some resins, for example,silicone rubber, maybe a liquid and could not involve heating. The material is then melted using the frictional action of a reciprocating screw that goes along with heater bands. The molten plastic is then fed through the nozzle and into a mold cavity. It may look easy, but injection molding is usually a very difficult method. While in the mold cavity, the material cools and freezesto the arrangement of the cavity. When the part has hardened, the moveable platen that the mold is mounted unlocks and the part is removed using ejector pins.

What Are The Merits Of Low Volume Manufacturing?

LowVolume Injection Moldingis a mainly popular choice formany product types since it lets for a restricted investment in materials while giving rapid access to, markets, boosts design elasticity and also a bridge to prototypes and also providespossible high volume production. Here are some unique qualities of a low volume manufacturing process.

- It covers various processes:It can be attained through short-run plastic injection molding, for example, and low volume manufacturingcan also refer to 3D printing.

- It uses different materials: In low volume injection molding, hardened, super durable tool steel is not always essential to make a mold or tool. Soft materials such as aluminium can be utilized in the manufacturing process. Asaluminummolds can give plenty of durability according to your requirements.

- It bridges a gap: Sometimesit is also called as bridge manufacturing. Low volume manufacturing covers quantities better than prototype production, but less than full-scale mass manufacturing.

Advantages Of Low Volume Injection Molding

Here are some advantages of the Low Volume Injection Moldingprocess.

- Mold cost: Low volume molds are usually cut from a high-quality grade of aluminium that is easier forthe machine and adjust than hardened steel.

- New product launches: It needs only a modest investment that enables the product to obtain to market quicker. And it also restricts the monetary loss if a product is not successful in the marketplace.

- Technology: Low volume tools may be more viable if you anticipate a short product life.

- Low volume requirement: Many times, only a few thousand parts are needed to meet the requirements of thewhole production run.